Fiber Optic Tech

What is a Fiber Array (FA) ?

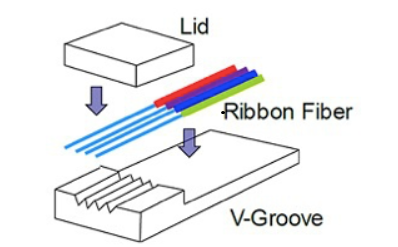

A fiber array (FA) is an arrangement where a bundle of optical fibers or a fiber ribbon is mounted onto a substrate with predefined spacing, typically using a V-groove baseplate.

In optical communications, a fiber array mainly consists of a baseplate, a pressure plate, and optical fibers. Multiple grooves are precisely cut into the substrate, and the optical fibers are inserted into these grooves, then tightly pressed and fixed in place by the pressure plate.

Fiber arrays require extremely high standards for both materials and manufacturing processes. Precise positioning is primarily achieved through the accurately etched V-grooves. Special cutting and micromachining techniques are used to fabricate the V-grooves with high precision, ensuring accurate fiber alignment. Bare fibers, with their coatings removed, are placed into the V-grooves. Through ultra-precision processing, the fiber cores are precisely aligned within the grooves to minimize connection loss. The fibers are then pressed and bonded using adhesive. Afterward, the fiber end faces are optically polished, and the array is coupled to a PLC (Planar Lightwave Circuit) chip to form a complete fiber array assembly.

Additionally, the encapsulation materials for fiber arrays must exhibit excellent flowability, moisture resistance, waterproof properties, and long-term stability to ensure reliable performance over time.

Product Structure and Features

Fiber Types: Single-mode fiber (SMF), multimode fiber (MMF), polarization-maintaining fiber (PMF)

Substrate Materials: High-precision silicon or glass

Fixation Method: UV adhesive curing for long-term stability

End-face Processing: PC (physical contact) polishing or APC (angled physical contact) polishing to effectively reduce return loss

Fiber Arrays offer outstanding advantages such as high fiber alignment precision (less than 1μm), low insertion loss (typically <0.2dB), and high return loss (typically >50dB). Channel number, fiber pitch, and end-face types can be customized according to application requirements.

Common Specifications Comparison

| Parameter | Standard SMF | MMF | PMF |

| Fiber Pitch | 127μm / 250μm | 127μm / 250μm | 250μm |

| Channel Count | 2–128 | 2–64 | 2–64 |

| Insertion Loss | <0.2dB | <0.3dB | <0.4dB |

| Return Loss | >50dB | >45dB | >45dB |

| Operating Wavelength | 1310/1550nm | 850/1300nm | 1310/1550nm |

(Note: Different parameters can be customized based on client requirements.)

Overview of Manufacturing Process

Precision V-Groove substrate fabrication (MEMS process)

Fiber placement and sub-micron alignment

UV adhesive curing and preliminary inspection

Precision cutting and end-face polishing

Factory performance testing: insertion loss, return loss, etc.

Major Application Fields

1. Optical Communications

Used in AWG, PLC, optical switches, and other modules to achieve efficient multi-channel optical signal coupling and distribution.

Typical Example: In 100G/400G optical modules, Fiber Arrays enable the coupling and separation of high-speed optical signals, greatly enhancing integration density and performance.

2. Silicon Photonics Integration

Serves as the I/O interface for silicon photonic chips, achieving high-speed, low-loss optical interconnections.

Typical Example: In data center silicon photonics modules, Fiber Arrays connect silicon photonic chips with multimode or single-mode fibers, enabling high-speed short- or medium-range data transmission.

3. Optical Sensing Systems

Acts as a signal acquisition and distribution platform in systems such as FBG (Fiber Bragg Grating) and Raman sensors.

Typical Example: In infrastructure health monitoring systems for bridges and tunnels, Fiber Arrays couple multiple FBG sensors to achieve wide-area, distributed strain and temperature detection.

4. Laser Array Coupling Applications

Connects VCSEL, DFB, and other laser arrays to achieve high-density laser output collection, suitable for data centers and LiDAR systems.

Typical Example: In LiDAR (Light Detection and Ranging) systems, Fiber Arrays facilitate multi-channel laser transmission and reception, improving spatial resolution and detection accuracy.

5. Optical Testing and Measurement

Serves as an efficient input/output interface for optical device and module testing, improving testing efficiency and accuracy.

Typical Example: In DWDM device test platforms, Fiber Arrays enable simultaneous measurement of multiple channels, greatly enhancing production yield and testing throughput.

Key Factors to Consider When Choosing Fiber Arrays

When selecting a Fiber Array product, key parameters should be carefully considered to ensure optimal application performance:

Insertion Loss: Directly affects signal transmission efficiency — the lower, the better.

Return Loss: Indicates the amount of reflected signal — higher values ensure more stable system performance.

Channel Uniformity: Consistency among multiple channels ensures overall system stability.

Fiber Alignment Precision: Especially crucial for high-speed and silicon photonics applications, where fiber alignment error must be extremely small (typically within ±0.5μm).

Environmental Reliability: Temperature and humidity resistance to guarantee long-term stable performance.

Customization Flexibility: Ability to tailor channel count, pitch, end-face polishing angle, etc., to facilitate system integration.

A high-quality Fiber Array not only enhances system performance but also reduces maintenance costs and overall investment risks.

Future Development Trends

With the rapid advancement of 5G, artificial intelligence, quantum communications, and data centers, Fiber Arrays are evolving towards:

Higher channel counts

Smaller fiber pitches

Ultra-low insertion loss

Greater stability and miniaturization

Intelligent assembly and testing

Thus, they are becoming the core foundational components of next-generation high-speed, broadband optical interconnection systems.

Industry Trend Predictions

Silicon Photonics Boom: As silicon photonics technology is increasingly applied on a large scale, Fiber Arrays will deeply integrate with silicon-based optoelectronic chips, leading to surging demand.

Data Center Upgrades: The deployment of 800G and 1.6T optical modules will drive significant growth in multi-core Fiber Array requirements.

Emerging Automotive Optical Communication: The rise of autonomous driving demands high-speed data exchanges, spurring innovations in compact, vibration-resistant Fiber Array technologies.

Quantum Communication Breakthroughs: Technologies such as multi-photon entanglement and quantum key distribution require Fiber Arrays with even lower loss and higher uniformity.

Smart Manufacturing and Inspection: Machine vision, AI-assisted detection, and other new processes will improve Fiber Array production yield and consistency.

As a key node linking the microscopic and macroscopic worlds, Fiber Arrays are continuously expanding their application boundaries and will play an increasingly vital role in the future intelligent interconnected society.