Fiber Optic Tech

Is the gold finger of an optical transceiver really made of gold?

Do you know how an optical transceiver maintains stable transmission? Today, we will introduce the weapon for maintaining stable transmission of optical modules - the gold finger.

An optical transceiver typically consists of optical laser, a functional circuit board (PCB), a shell, and other parts. And, the gold finger is a critical part of signal transmission. The "gold finger" of an optical transceiver refers to the gold-plated conductive contacts on the PCB board, which are mainly used to connect to other devices. The gold finger is responsible for transmitting signals and power, and ensuring the normal operation of the optical transceiver. Additionally, the thickness of the gold plating on the gold finger directly affects the transmission quality of the optical module, such as issues like current and voltage fluctuations or abnormal temperature increases.

So, is the "gold" in the gold finger actually made of real gold? We believe you will find the answer after reading the following content.

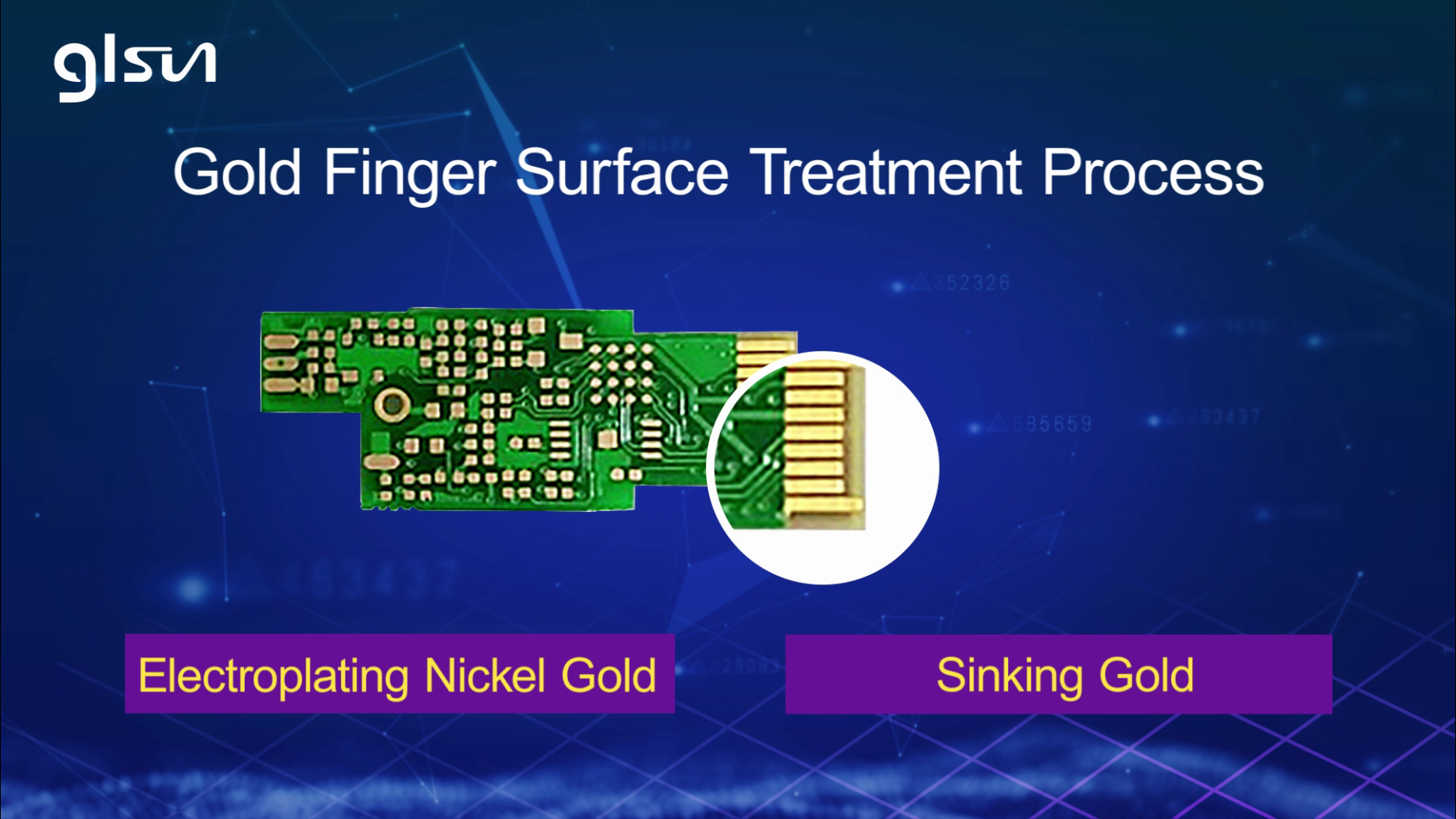

The most common "gold" used in gold fingers falls into the following two types:

1. Electroplating Nickel Gold

Gold plating is a surface treatment process for PCBs. With a thickness ranging from 3-50 μm, it has excellent conductivity, oxidation resistance, and wear resistance, making it widely used in gold finger PCBs that require repeated plugging and unplugging. Due to the high cost of gold plating, it is only applied to gold finger and other localized gold plating treatment.

Advantages of Electroplating Nickel Gold

- Superior Conductivity

- Anti-Oxidation

- Anti-Corrosion

- Reduce Contact Resistance

- Wear Resistance

2. Sinking Gold

Sinking gold typically have a thickness of 1 μm, but can reach up to 3 μm. Compared to electroplating nickel gold, sinking gold has higher conductivity, flatness, and solderability, making it widely used in high-precision PCBs with components like key buttons and IC bindings. For gold finger PCBs that do not require high wear resistance, full-board sinking gold process can also be chosen. The cost of sinking gold process is much lower than that of electroplating nickel gold process.

Advantages of Sinking Gold

- Superior conductivity

- Highflatness

- HighWeldability

- Low Cost

With the development of electronic information, the Internet, and industrial manufacturing, gold fingers are widely used in optical transceiver module, memory cards, USB interfaces, and more.

Now, do you know what kind of "gold" is used in the gold finger?