Fiber Optic Tech

Introduction of BOSA Packaging

The most important and core part of optical communication is the optical module. The basic function of the optical module is to complete the optical electrical or electrical optical conversion function of optical signals, and its interior is mainly composed of optical devices, functional circuits, and optical interfaces. Among them, optical devices are the main components of optical modules, one is TOSA (Transmitting Optical Sub-Assembly), and the other is ROSA (Receiving Optical Sub-Assembly). The optical devices used in early optical modules were separated from each other, and with the development of miniaturization, the combination of the two became BOSA (Bi-Directional Optical Sub-Assembly).

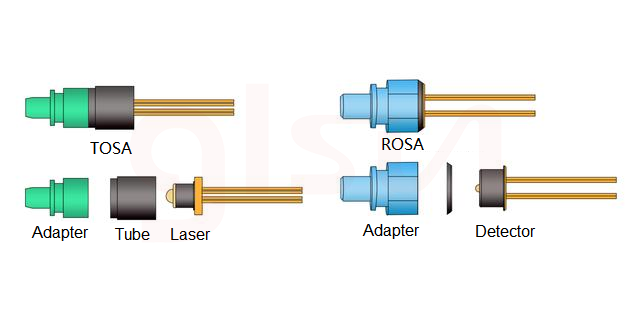

Introduction of TOSA & ROSA

TOSA (Transmitter Optical Sub assembly) is mainly composed of lasers, tube sleeves, and adapters, as well as isolators and adjustment rings in long-distance optical modules. With light sources (semiconductor light emitting diodes or laser diodes) as the core, LD chips, monitor photodiodes (MD), and other components are packaged in a compact structure (TO coaxial package or butterfly package). The TOSA formed is mainly used for converting electrical signals into optical signals (E/O conversion). ROSA (Receiver Optical Sub assembly) is mainly composed of detectors and adapters. In high data rate optical fiber modules, PIN or ADP photodiodes and TIAs are usually assembled in a sealed metal housing, and the optical receiving components are mainly used to to convert optical signals into electrical signals (O/E conversion).

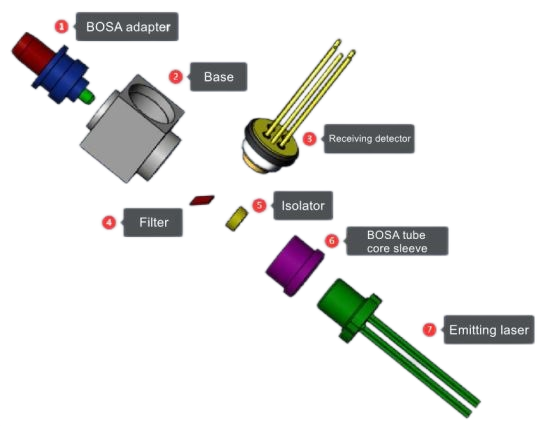

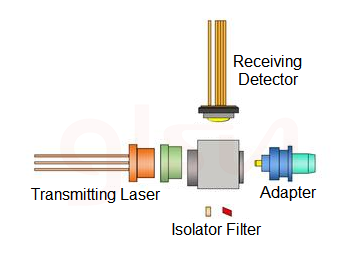

Introduction of BOSA

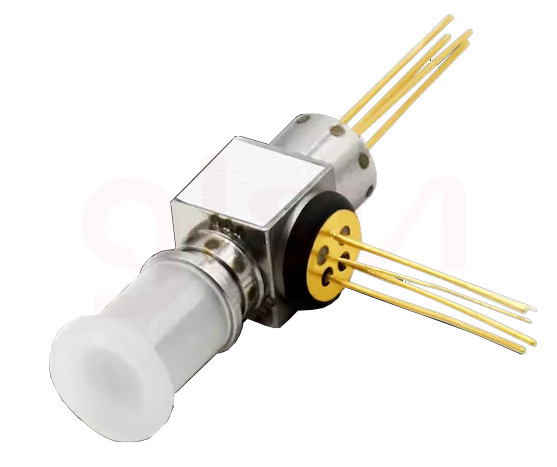

BOSA (Bi-Directional Optical Sub-Assembly) refers to a single fiber bidirectional optical device, which is mainly composed of a transmitting laser, a receiving detector, an adapter, a filter, a base, an isolator and a tube sleeve. It is also a component that integrates TOSA and ROSA Integrate the transceiver (LD and PIN/APD) of a light source through a coaxial coupling process, plus a separator, optical fiber, and other components. The main function is to convert electrical signals and optical signals into each other.

Key Components of BOSA

1. DFB laser diode as transmitter and PD-TIA as receiver

2. Filters, 0°and 45°, for transmitting and receiving in optical paths

3. Isolator, selecting different isolators based on different wavelength. If this isolator is omitted due to the cost and its process, the direct trouble is that the output eye pattern will shake severely.

4. Adapter and pigtail, choose according to cost and application scenarios

Production Process of BOSA

Main Process:Marking—Splitter Installation—LD Aassembly—Surface Detection and Spot Welding—Transmitting Coupling—Welding—Receiving Coupling—Glue Sealing—Transmitting and Receiving Parameters Detection.

1. Marking: It is to use a laser to print an ID on the outside of the metal structure of the component, and enter its parameters into the system for easy tracking and inspection.

2. Splitter Installation: The function of splitter is to separate the received and emitted light in the optical fiber. The LD is installed on a metal structure equipped with a splitter.

3. Surface Detection and Spot Welding: Check the press mounting effect of the assembled metal structure with LD under a microscope to see if there are any adverse conditions such as pin tilt. After checking that there are no problems, laser spot welding will be performed on the LD and the structural parts to fix the LD.

4. Transmitting Coupling and Welding: By adjusting the position of SC connector and Laser Diode, the light emitted by LD can be coupled into the optical fiber of SC connector as much as possible. After the adjustment is completed, laser spot welding is conducted to fix the SC joint part and laser diode.

5. Receiving Coupling and Glue Sealing: Adjust the position of PD and the structural part with LD installed, so that more optical signals from the optical fiber are coupled to PD to improve the receiving sensitivity of PD. After the adjustment meets the index requirements, the PD and the structural part are adjusted Glue sealing to fix PD.