Fiber Optic Tech

High-density and High-speed Transmission in Data Centers - MPO Fiber Optic Patch Cables

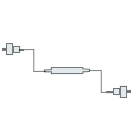

Data centers are the backbone of the internet, and as the demand for data continues to grow, so does the need for faster and more efficient ways to transmit information. In data centers, MPO (Multi-Push On) fiber optic patch cords are increasingly playing an important role due to their small size, high-density and high-speed transmission, and the ability of a single connector to support multiple optical fibers.

What are the definitions and differences between the male and female ends of MPO fiber optic connectors?

Male MPO and female MPO need to be used together. The male connector has guide pins and the female connector does not. The accurate docking of the male and female headers is achieved through PINs.

Generally speaking, for optical modules that use multi-core MPO optical interfaces, their interfaces are male and have guide pins (PIN pins) inside the interface. For example, the optical interface of the 100GBASE-SR4 optical module is a male MPO, and the MPO optical jumper connected to it must use a female MPO optical fiber connector.

The polarities of MPO fiber optic patch cords are divided into Type-A, Type-B and Type-C.

Type-A

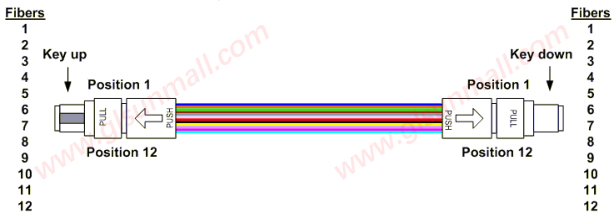

Type A MPO fiber optic jumper, taking the 12-core Type A: 1-1 MPO fiber optic jumper as an example, the fibers are arranged in a single row, as shown in Figure 1, Type A: 1-1 MPO fiber optic jumper Each fiber has a serial number as follows:

1. At one end of the MPO optical fiber jumper, the optical fiber is fixed in the MPO optical fiber jumper connector. Viewed from the end face of the connector, the connector key is facing upwards, and the continuous serial numbers of the optical fibers from left to right are 1,2,3,4…12.

2. At the other end of the MPO optical fiber jumper, the optical fiber is fixed in the MPO optical fiber jumper connector. Viewed from the end face of the connector, the connector key is also facing upward, and the continuous serial number of the optical fiber from left to right is also 1,2,3,4…12.

Figure 1 - Type A (key up to key down)

Type-B

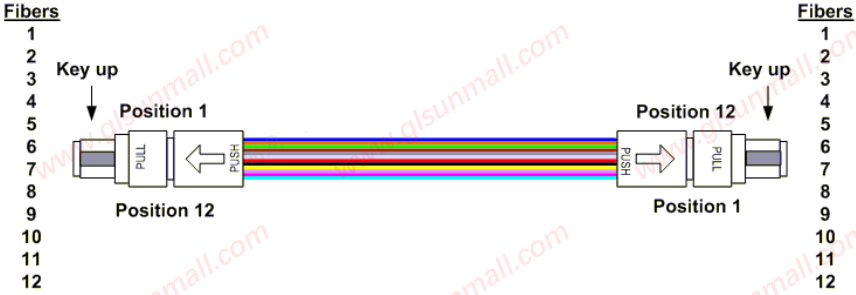

Type B MPO fiber optic patch cord takes the 12-core Type B as an example, in which the fibers are arranged in a single row. As shown in Figure 4, each fiber in the Type B has a serial number as follows:

1. At one end of the MPO optical fiber jumper, fix the optical fiber in the connector interface of the MPO optical fiber jumper from left to right. Viewed from the connector end face, the connector key is facing upwards, and the optical fibers are numbered from left to right. It is 1, 2, 3, 4…12.

2. At the other end of the MPO optical fiber jumper, the optical fiber is fixed in the connector interface. Viewed from the end face of the connector, the connector key is facing upward. The optical fibers are numbered consecutively from left to right in reverse order, and are numbered 12,11,10,9…1.

Figure 2 - Type B (key up to key up)

Type-C

Type C MPO fiber optic patch cord, taking the 12-core Type C as an example, the fibers are arranged in a single row. As shown in Figure 3, each fiber of the Type C has a serial number as follows:

1. At one end of Type C, fix the fiber in the connector of the MPO fiber jumper. Viewed from the end face of the connector, the connector key is facing upward. The fibers are numbered from left to right. 1, 2, 3, 4…12.

2. At the other end of the Type C, the fibers are flipped from left to right in the connector of the MPO fiber optic patch cord, as shown in the figure, from the end face of the connector (from left to right ) Look, with the connector keys facing up, the serial numbers of the fibers are 2,1,4,3,6,5…12,11.

Figure 3 – Type-C (flip in pairs, key up to key down)

How to choose high-quality MPO fiber optic patch cord?

MPO optical fiber jumpers are widely used in data centers. Based on high-speed and high-density optical fiber cabling and data transmission, it can be said that its quality determines the security, stability, reliability and sustainability of the entire data center network. Therefore, in terms of optical fiber cabling in data centers, it is recommended to use high-quality MPO fiber jumpers! So, how to choose high-quality MPO fiber jumpers? You can refer to the following aspects:

First of all, MPO connectors meet the GR-1435-CORE and IEC 61754-7 standards. The optical fibers used in MPO fiber optic patch cords comply with the mechanical performance, environmental performance, optical performance, geometric characteristics and other requirements of the IEC 60793 series of standards. Among them, many Mode fiber meets DMD differential mode delay test;

Secondly, MPO optical fiber jumpers should choose low-loss, high-return-loss MPO connectors to improve the stability of the communication system and channel loss margin;

Finally, the optical cables used in excellent MPO optical fiber jumpers can meet the safety requirements for cables in relevant international standards. For example, the cables can pass bundle combustion or OFNP pressurized fire resistance level tests.

According to the customer's application requirements, the optical cables used in MPO fiber optic patch cords can be selected with different safety levels, such as bundled combustion or OFNP pressurized fire resistance level; selected MPO connectors meet and exceed GR-1435-CORE and IEC 61754- 7 standards to ensure high return loss, low loss and connection interchangeability; the optical fiber used meets and exceeds the requirements of geometric properties, optical properties, mechanical properties and environmental performance in the IEC 60793 series of standards. Among them, multi-mode optical fiber passes DMD Differential mode delay testing ensures the system stability of high-speed (such as 400Gb/s, 800Gb/s, etc.) optical fiber communication applications.

GLSUN's MPO cables include the following advantages:

(1) The product 100% passes the optical performance test;

(2) Small size, which can greatly increase the wiring density and save wiring space;

(3) Use high-quality imported raw materials (SENKO, USCONEC) and comply with RoHS;

(4) It can support customization of various lengths, polarities, and core numbers to meet your customized needs;

(5) The modular design is plug-and-play, which can save a lot of installation time and reduce network management and maintenance costs;

What should we pay attention to installation?

Before installation, you must confirm that the dust cap of the MPO fiber optic connector and the dust cap of the mated MPO adapter have not fallen off or been pulled out to prevent dust from entering or the end face being damaged. It is recommended to clean and inspect the ferrule fiber end face of the MPO fiber optic connector to remove any dirt. During installation, remove the dust cap, clean it, and then the MPO fiber optic connector into the adapter. Generally, hearing a crisp "click" sound indicates good docking.

After installation, make a reasonable plan for the routing of the jumper to ensure the minimum bending radius of the cable. The fixed cable should not be too tight. Magic ties should be used for buffer fixation. If the cable length is slightly longer, the excess optical cable can be coiled and fixed in equipment or space suitable for fiber storage.